In today’s hyper-competitive industrial landscape, where efficiency, uptime, and reliability can make or break a business, TPM (Total Productive Maintenance) emerges as a powerful operational tool. But implementing TPM is not just about fixing machines, it’s about embedding a culture of continuous improvement, ownership, and operational excellence. This is where expert TPM consultants make all the difference.

What is TPM in Manufacturing?

Total Productive Maintenance is a comprehensive approach to equipment maintenance that aims to achieve perfect production, zero breakdowns, zero defects, and zero accidents. TPM goes beyond the maintenance department, involving every employee, from top management to shop-floor workers, in proactive and preventive maintenance initiatives.

It’s about empowering operators to take ownership of the equipment they work with daily, identifying potential issues early, and keeping machines running at their peak. This cross-functional, people-centric methodology not only reduces downtime but also enhances productivity and employee morale.

Why You Need TPM Consultants (Total Productive Maintenance)

While the philosophy behind TPM sounds simple, effective implementation requires in-depth knowledge, structured frameworks, and cultural transformation. This is where TPM consultants come into play. These experts assess your current plant conditions, identify gaps, train teams, and set up sustainable systems for long-term success.

Here’s how professional TPM consultants help organizations:

- Conduct TPM maturity assessments

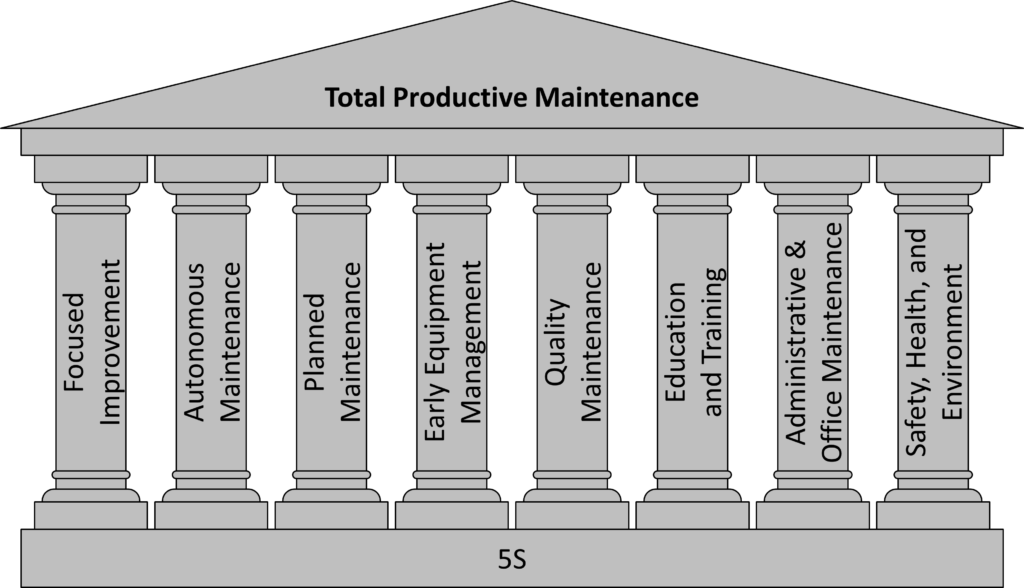

- Design and implement TPM pillars (Autonomous Maintenance, Planned Maintenance, Focused Improvement, etc.)

- Facilitate Kaizen activities and cross-functional workshops

- Train shop-floor and maintenance teams in best practices

- Develop dashboards and visual systems to track performance

- Embed a performance-driven culture with accountability

Benefits of Engaging TPM Consultants

Organizations that partner with experienced TPM consultants witness a wide range of tangible and intangible benefits. A few outcomes include:

- Reduced unplanned downtime

- Enhanced machine availability and performance

- Increased operator engagement and ownership

- Improved safety and reduced workplace incidents

- Lower maintenance costs and spare parts consumption

In real-time deployments, even a 30–40% improvement in Overall Equipment Effectiveness (OEE) can be achieved when TPM principles are correctly embedded. But the real magic lies in how this transformation energizes the organization’s culture, making teams proactive instead of reactive.

TPM Consultants in Action – Beyond the Shop Floor

A successful TPM journey is not confined to machines. It reflects across departments, from production and quality to logistics and HR. TPM consultants work closely with leadership to align TPM with business goals and integrate it with digital tools, lean manufacturing practices, and Industry 4.0 readiness.

They also introduce capability-building initiatives, including TPM training modules, SOP creation, and system audits to drive sustenance. As a result, operations become more predictable, responsive, and efficient.

Faber Infinite Consulting: Driving TPM Success Stories Across Industries

At Faber Infinite Consulting, our seasoned TPM consultants have helped organizations across industries, from pharmaceuticals and engineering to packaging and process manufacturing, achieve remarkable shifts in operational excellence.

Through our hands-on approach, we’ve enabled teams to:

- Create autonomous maintenance checklists tailored to equipment types

- Reduce changeover times using SMED techniques

- Build skills and confidence on the shop floor

- Establish proactive maintenance schedules

- Strengthen cross-functional problem-solving with continuous improvement workshops

One of our clients, a mid-sized manufacturing unit, experienced over 35% improvement in machine uptime within the first few months of TPM implementation—thanks to our practical yet people-driven methodology.

We believe in more than just fixing problems. We work with your team to build systems, train people, and design accountability frameworks that stick. Because true transformation doesn’t end with tools—it begins with people.

Faber Infinite’s Proven Approach to TPM Implementation

At Faber Infinite Consulting, our TPM (Total Productive Maintenance) methodology is built on a structured, impact-driven framework designed to improve equipment availability and reduce maintenance costs. Here’s how we typically roll out the TPM journey for our clients:

- Project Scoping & Baseline Assessment

The journey begins with a clear scoping phase to align expectations, define objectives, and establish key metrics for success. - Comprehensive Diagnostic Study

This includes initial facility visits, detailed data collection and analysis, stakeholder meetings, and hands-on assessments to identify key areas for improvement. - Customized Implementation Roadmap

Based on insights from the assessment, we create a tailored TPM dashboard, a detailed master plan, and a benefit tracking sheet to guide implementation. - Leadership Alignment & Capability Building

A leadership conclave and structured training sessions are conducted to ensure strategic alignment and build internal capabilities. - Transformation Interventions

Once goals are finalized, implementation begins through focused interventions across autonomous maintenance, preventive practices, and continuous improvement projects. - Sustenance through Reviews & Audits

Long-term success is driven by periodic audits, performance reviews, and robust governance to ensure sustained impact and continuous improvement.

Ready to Begin Your TPM Transformation?

Whether you’re just starting on your TPM journey or looking to reignite a stalled implementation, Faber Infinite Consulting can be your transformation partner. Our TPM consultants blend global best practices with deep operational insights to help you unlock the full potential of your plant and people.

Let us show you how continuous improvement can be more than a concept, it can be your competitive edge.

Connect with us at www.faberinfinite.com | consulting@faberinfinite.com

Let’s co-create your journey towards leaner, smarter, and more efficient operations.

Case Study : Total Productive Maintainance

Case Study 1: Operational Excellence in Plastic Manufacturing Industry

Challenges:

- Long lead times and delayed deliveries.

- Low equipment and mould uptime is causing production loss.

- Excess finished goods inventory alongside frequent stock-outs.

- Low manpower productivity and inefficient planning.

Approaches:

- Conducted Value Stream Mapping to reduce bottlenecks and improve Value Adding Ratio.

- Implemented structured inventory management with Kanban and Pull Production.

- Reduced mould changeover time using SMED principles.

- Applied Total Productive Maintenance (TPM) to boost equipment & mould uptime.

- Improved manpower productivity through Time & Motion studies and Cellular Layout design.

- Established better planning mechanisms to reduce WIP inventory.

Results:

- Lead time reduced by 30%.

- Finished goods inventory reduced by 32% with zero stock-outs.

Case Study 2: Operational Excellence in Warehouse Management

Challenges:

- Low inventory turns below FMCG benchmarks.

- High wastage due to product expiry and poor inventory management.

- Low fleet reliability and high transit breakdowns.

- Lack of structured warehouse practices and poor information flow.

- Absence of a continuous improvement culture.

Approaches:

- Designed improved warehouse layout and implemented Golden Rules of Warehouse Management.

- Rolled out Kanban system for inventory optimization and replenishment.

- Trained 300+ employees on Lean, TPM, Inventory & Warehouse Management.

- Established TPM framework to enhance fleet reliability and reduce breakdowns.

- Created OPLs and SOPs for better autonomous maintenance and workplace management.

- Introduced Kaizen modifications to improve pallet movement and dispatch processes.

Results:

- Cash release of ~$1.1 million USD.

- Inventory turns improved by 25%.

- Fleet average availability improved by 27%.

- Transit breakdowns reduced by 45%.

- Trip capacity utilization improved by 13%.

- Overall Truck Effectiveness (OTE) improved by 20%.

Contact us for TPM Consulting